Manufacturing Control System

SMTT aim to be among the global industry leaders in the OEM & EMS industry. Our continuous investment in manufacturing facilities, helps us to provide customers with cost optimization and innovative solutions.

SMTT aim to be among the global industry leaders in the OEM & EMS industry. Our continuous investment in manufacturing facilities, helps us to provide customers with cost optimization and innovative solutions.

Laser Marking Scanning & PCB Completion

Barcode Validation

Laser Mark Capability

Production & IPQA Verification

2D Barcode Printing

2D Barcode Printing

Standardize Database Server

Printing & Reprinting System

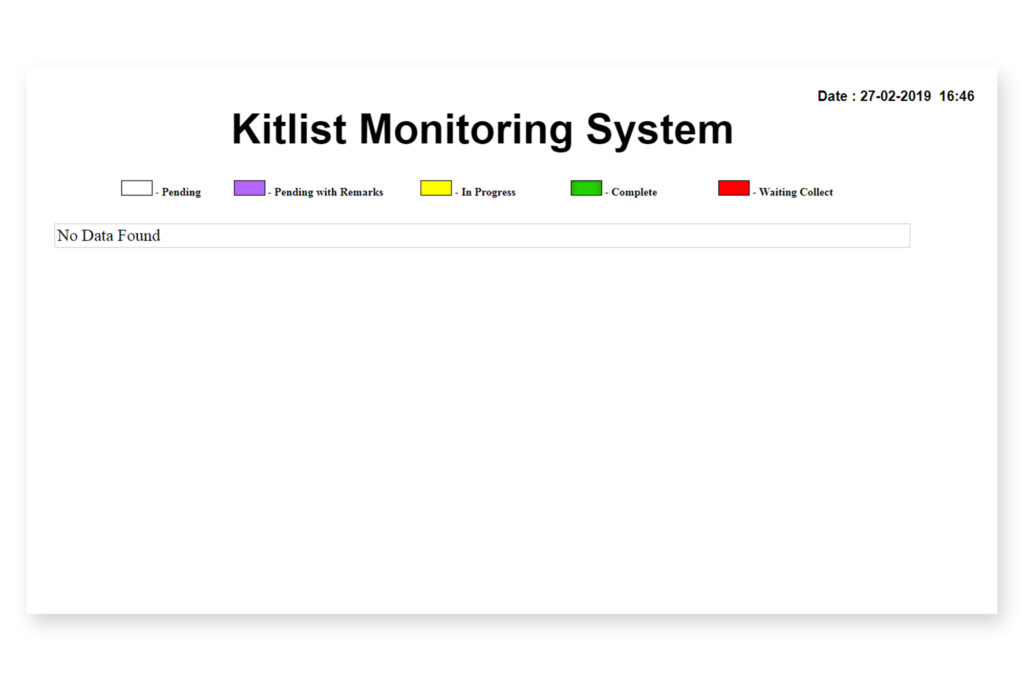

Real time monitoring of material Kitting issuance time and preparation time.

Integrate Store and WCG material preparation as system will trigger with colour status.

Reduce production and inventory turnaround leadtime through efficient material kitting.

Continous Investment

Leveraging Innovation

Improving the user experience

Improve Inventory Turns-Reduce inventory turnaround time and holdings

Inventory visibility– helps to identify priorities (replenishing for stock or a stock-out)

Improving the user experience

VMI Interface